- дом

- Сервосистема

- Solution of SD700 on Pillow Packaging Machine

Industry introduction

Pillow packaging machine is used for sealing and packaging bulk goods. The machine uses bag making, feeding, sealing, cutting, forming, and other processes to achieve the purpose of sending the product into the packaging film and heat sealing the three sides into a bag.

The machine is widely used in high-speed packaging of food, tableware, sanitary products, medicine, hardware parts, labor insurance products, and other industries-related products. The most common biscuits, candies, and tableware in daily life are all packed into bags by pillow wrapping machines.

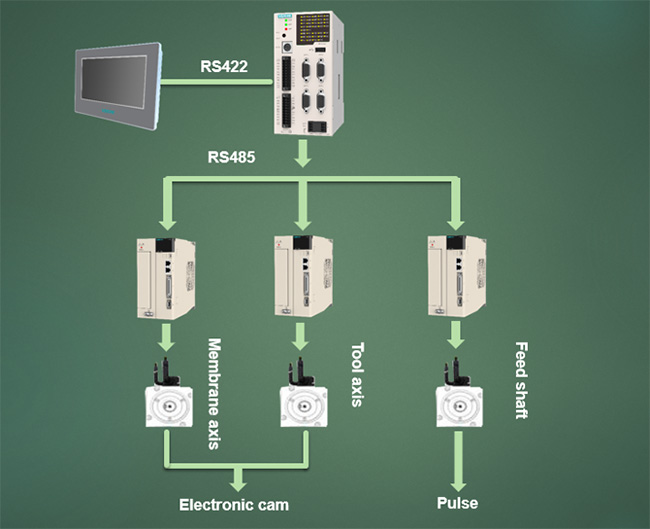

System topology

Program highlights

1. The control system uses the VEICHI V5 series of motion controllers, relying on the controller's electronic cam function and high-speed computing processing to ensure the high response of the system. The controller and SD700 series servo products have strong anti-interference performance, and the system is stable and reliable in mass use.

2. Support single-section belt and multi-section belt feeding, a single set of the program supports the number of cutters that can be set (single knife, double knife, three knives, five knives), support variable-length material packaging.

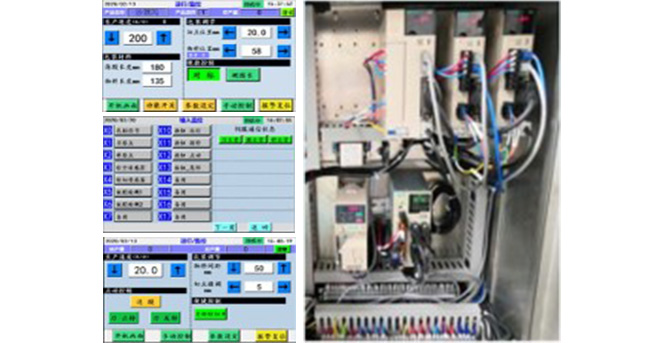

3. Powerful host computer software makes debugging easier. System debugging only needs to set necessary parameters, debugging is fast, and it supports one-key writing of servo parameters.

4. Combining on-site technology and load conditions, select a dedicated servo motor to make the load operation more stable and accurate.

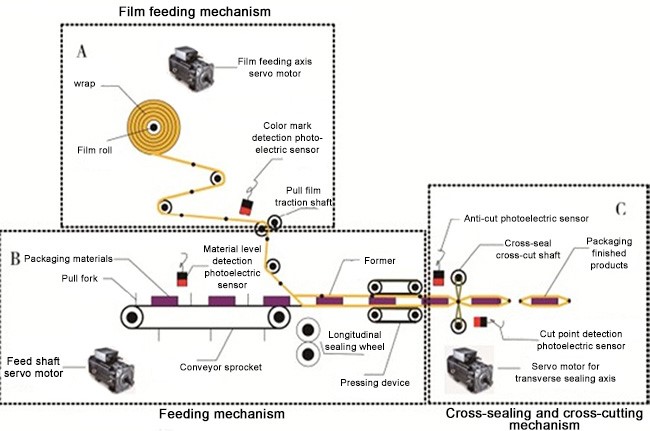

Process principle

The packaging process of the pillow packaging machine is achieved by the coordinated actions of the feeding shaft, the film pulling shaft, and the cutter shaft to achieve the packaging purpose. The feed shaft drives the shift fork to push forward and feed the material, and the sprocket of the feed shaft is calibrated every turn to ensure the accuracy of the feeding position. The film axis drives the packaging film to accurately feed the film according to the set bag length, and the color code signal is detected in the color code mode to compensate and correct the film feed position. The coordinated operation of feeding and film feeding ensures that the materials are accurately fed into the packaging film. The cutter position compensation correction is carried out for each revolution of the cutter shaft, and the cutter linear speed is maintained in the material cutting synchronization zone.

Technical index

Speed index: single-pole 250-300 packs/min packing speed of shift fork model runs smoothly.

The variable-length packaging mode of the belt model supports a maximum packaging speed of 35 m/min.

Accuracy index: color code accuracy ±0.5mm.

Application

Variable length packaging interface

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Оставить сообщение

Оставить сообщение