- дом

- Сервосистема

- Solution of SD700 on Six-axis Welding Robot

Industry introduction

The six-axis welding robot is to attach welding tongs or welding (cutting) guns to the final shaft flange of the industrial robot. A mechanism that enables welding, cutting, or thermal spraying. It can be used with six servo drives to control, and the action is very flexible. It can be welded three-dimensionally and irregularly in any direction. It is a multi-purpose, reprogrammable automatic control operating machine. With three or more programmable axes, it has the characteristics of compact structure, flexible movement, and stable work. It is widely used in the field of automated welding production.

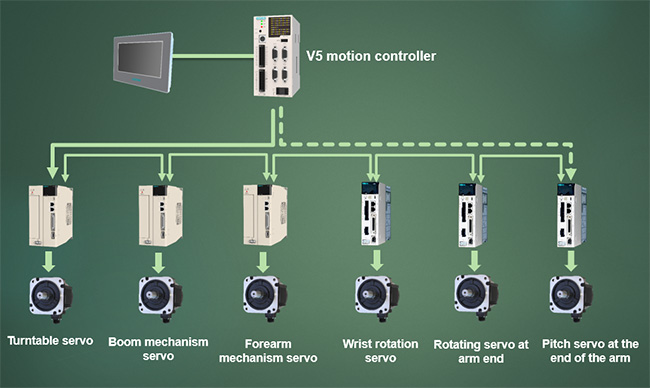

System topology

Program highlights

1. The man-machine interface is centrally controlled to realize recipe parameter setting, production data monitoring, output counting, and the operation is more intelligent and simple.

2. The EtherCAT bus operation controller integrates the EtherCAT master solution. It can realize multi-axis coordinated motion, high-speed point motion, and real-time rapid response control. Make the moving parts complete the welding action in accordance with the expected motion trajectory and motion parameters.

3. VEICHI SD700 EtherCAT bus type servo drive has ultra-high response frequency. The speed range is wide, the synchronization performance is excellent, the anti-interference ability is strong, and the master station is perfectly matched.

Process principle

The six-axis welding robot is mainly composed of a wrist mechanism, an arm mechanism, and a slewing mechanism:

1. Wrist mechanism: including the pitch joint at the end of the wrist, the revolving joint at the end of the wrist, and the revolving joint around the axis of the wrist as a whole. The motor at the end of the wrist is located at the end of the arm, and the power of the first two action joints is transmitted by the two servo motors using a coupling to connect the long mandrel, and bevel gear is used to change the direction. And use the timing belt to transmit the power to the end of the wrist. The whole wrist swivel joint is driven by a servo motor to drive a synchronous belt wheel to realize the overall movement around the axis.

2. Arm mechanism: Including the pitch joint of the forearm around the horizontal axis and the pitch joint of the big arm around the horizontal axis. The forearm pitch joint is transmitted by the servo motor to the small wheels of the gear set through the timing belt, and then the power is finally transmitted to the forearm-boom rotary joint shaft through the involute cylindrical spur gear. The joint servo motor, timing belt wheel, and gear set are all arranged on the boom. The large arm pitches joint servo motor is located on the waist base. After the power is output from the motor shaft, it is transmitted to a set of spur gears via a timing belt wheel. Then the big gear of the spur gear set is transferred to the boom pitch joint axis.

3. Rotary mechanism: The weight of almost the entire equipment, such as the wrist and arm mechanism, must be loaded on the rotary shaft. Therefore, the power of the servo motor of the slewing mechanism is directly transmitted to the joint shaft by a set of worm gears through the addition of a reducer.

Technical index

The maximum working radius can reach 1400mm.

The repeat positioning accuracy can reach 0.05mm.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Оставить сообщение

Оставить сообщение